As coronavirus-driven shelter-in-place orders keep more parents and kids at home, kids eyewear retailer Fitz Frames is keeping pace with an increased demand for its glasses. The state of Ohio has deemed the web-only retailer as an essential business, which allows its manufacturing facility to remain open.

The retailer launched its ecommerce site and app in August 2019. It was growing slowly over time, but it had its highest volume of sales in February and then doubled its sales from February to March as more states enacted shelter-in-place orders, says founder Heidi Hertel, without revealing exact figures.

“We anticipate that growth to continue through April,” Hertel says because more parents and kids will continue to stay at home and learn at home due to the coronavirus concerns.

The retailer currently sells six styles of glasses in a variety of colors for $95 each. It also offers a subscription plan for $185 per year, which includes two pairs of glasses and unlimited frames for the year.

On-demand, 3D-printed glasses

Fitz Frames isn’t a typical eyewear manufacturer and retailer; it produces glasses via 3D printing. Fitz Frames chose this method for production because of the freedom of design for frames, the material is more durable and—best of all for a small operation—there’s no inventory to manage and thus, no waste, Hertel says.

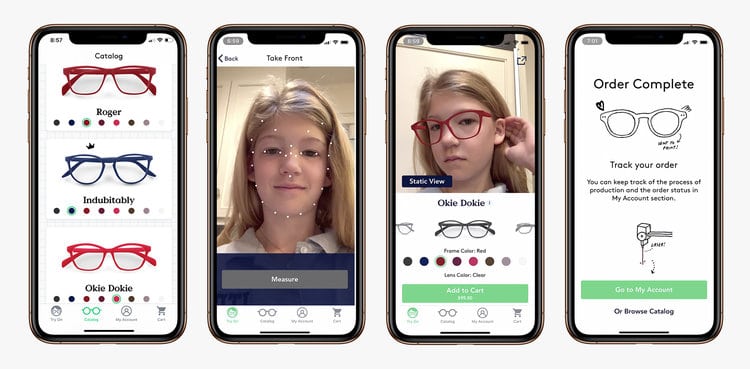

Shoppers download the Fitz Frames app and use the facial-mapping software, developed and designed by software development company Wizeline.

The front-facing camera pops users into a virtual try-on interface, which allows them to see the various styles and colors available to purchase. The facial-mapping technology snaps photos of the users’ front-on face and profile, taking 1,000 points of their face into account. After customers place their order on the app, the digital file is then sent to the 3D printers in its Youngstown, Ohio, facility. The frames are then printed based on the digital file, making every frame custom, down to the angle of their ears, the width of the bridge of their nose, where their temples sit, among many other factors. There are about 28 billion different combinations in the system that can be printed, the retailer says.

“Getting the temple measurement was really critical,” Hertel says. “At the beginning, we had to print several times as we tried to fit them properly, then print over and over again before we got it right.”

Once a shopper sends the digital file to the facility, it takes about two weeks for the retailer to print the glasses on one of its two 3D printers and ship them to the customer. Fitz Frames can also fulfill any prescriptions as its lens manufacturing facility is located about 10 minutes from its 3D-printing hub. It also sells nonprescription glasses, sunglasses and blue-light-filtering glasses for screen use. Hertel notes the blue-light-filtering glasses have increased in popularity as more people work from home and engage in more screen time.

And so far, the retailer has not experienced any shipping delays. “We say two weeks, but we’re averaging a bit under that,” she says. “We don’t want to overpromise given the uncertainty of the world right now.”

2020 and beyond

Although Fitz Frames’ focus is on kids, half of its customers are adults, Hertel says. “We talk to a lot of adults with various issues, like low ears or a wide nose bridge, who have had problems getting glasses to fit right for years.” So, the retailer is looking into developing designs for adults in the coming months.

But it’s hard to predict what the coming months will bring, Hertel says. She hopes to keep operating as normally as possible. Right now, Fitz Frames has the materials to produce glasses for customers who need them, she says.

However, Fitz Frames is looking into ways that it can use its 3D printing to provide supplies, such as personal protective equipment, to help medical professionals that are on the frontline of the coronavirus crisis. “We are looking into some developments there,” Hertel says.

Fitz Frames was initially born out of a desire to teach parents about eye health, Hertel says. Two of her children have worn glasses since they were 2 and 3 years old, which drove her to learn more about the optical industry for kids. “I was kind of stunned… Most everything was for adults, in stores, online, and it was the same offering because glasses are typically made overseas in huge quantities,” she says, adding that shoppers are lucky if a pair of glasses comes in more than one color or size.

But there’s a huge size differential in ages of kids who are supposed to be wearing all the same frames, she says. “That’s when I learned about the magic that is facial mapping and 3D printing,” she says.

Word of mouth has driven most of the eyewear retailer’s success with a high repeat order rate and customer satisfaction levels, Hertel says, without revealing more. Influencers on social media with significant followings who post about the glasses also help drive potential customers to its app.

Favorite