Steve Brandt, North American director of automated packaging solutions, Packaging by Neopost

It is often difficult to satisfy everyone—especially as it relates to shipping. Customers want fast shipping in sustainable packaging. Carriers want lower DIM [dimensional] weights. As a retailer, you want lower packaging and shipping costs. While this can seem overwhelming, there is a solution that can solve all of these packaging issues and more: automated packaging technology.

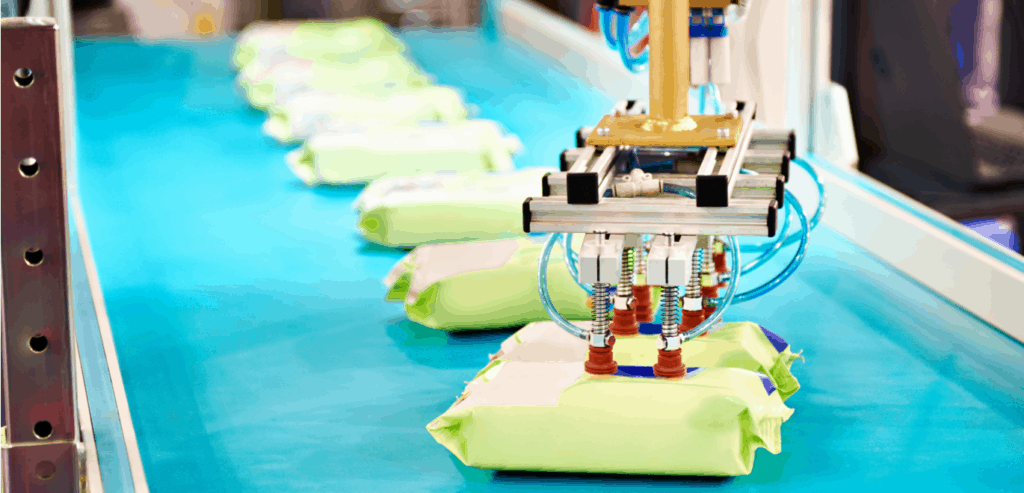

These innovative auto-boxing systems are now found at warehouses across the country, including Amazon’s. The state-of-the-art solutions measure, construct, seal, weigh and label each order in a custom-fit parcel in as little as seven seconds using only one operator. Some will also auto-box single- or multi-item orders as well as produce parcels for soft or hard goods without any additional equipment or operators needed.

These proven auto-boxing solutions generate the smallest parcel needed while optimizing all steps of parcel fulfillment, saving retailers on shipping and material costs, and even reducing the warehouse’s reliance on labor.

Amazon turned to these solutions to combat the labor shortage seen in warehouses across the country. As it gets harder to hire these positions, especially in packaging, the retailer saw the advantage automated packaging systems can have on warehouse efficiency. The technology creates custom-fit parcels so employees no longer need to spend time searching for the appropriate-sized shipping package and void fill, which can add a lot of time in getting the order out the door and into the customer’s hands.

The number of employees in the packaging department is also greatly reduced with these solutions so employees can be transferred to other departments to create more value and streamline the order fulfillment process across the entire warehouse.

Evaluating automated packaging systems

Although these solutions fix many of today’s shipping pain points, they are an investment. Before integrating these automated packaging solutions into a warehouse or distribution center, it is important to evaluate your specific packaging process and needs. To do this, you must:

- Research the automated packaging solutions in the market. While they may look similar, there are differences. For example, some solutions reduce package volume by only one dimension—height, while others will reduce by length and height.

There are even some systems that reduce parcel volume on every axis. These solutions allow for the absolute lowest DIM weight, and in turn, the lowest shipping cost. Be sure you find the solution that best fits your customers’ and your items’ demands and needs. - See the machine in action. Videos, infographics and photos are great, but nothing can beat viewing your potential new investment in person. Visit the machine and ask to speak to the warehouse manager and others who use the machine on a daily basis to really understand how it helps streamline order fulfillment.

- Complete a return on investment analysis. Do your homework to see how long it will be until you receive a full return on investment after installing an automated packaging solution in your warehouse or distribution center. This includes reviewing labor and shipping material costs as well as the time it takes to manually package each order. Some retailers have found it has taken them only six months to receive a full return on investment post installation of these innovative machines.

With automated packaging solutions, your shipping woes can be solved. After implementing these solutions, some retailers have seen a 50 percent reduction in shipping volume and 32 percent reduction in freight costs. Amazon was even able to eliminate at least 24 roles in its packaging department. With reduced freight costs, lower labor costs and less packaging materials used, an automated packaging solution can be your key to parcel packaging success.

Packaging by Neopost, part of Paris-based The Neopost Group, is a provider of postage meters, automated packaging systems and other mailing and shipping technology and services.

Favorite